PRODUCT

Head and claw precooler Chilling Screw

Product category:

Precooling Equipment

Spiral precooling machine

Large capacity spiral cooling machine

Head claw spiral cooling machine

Product introduction

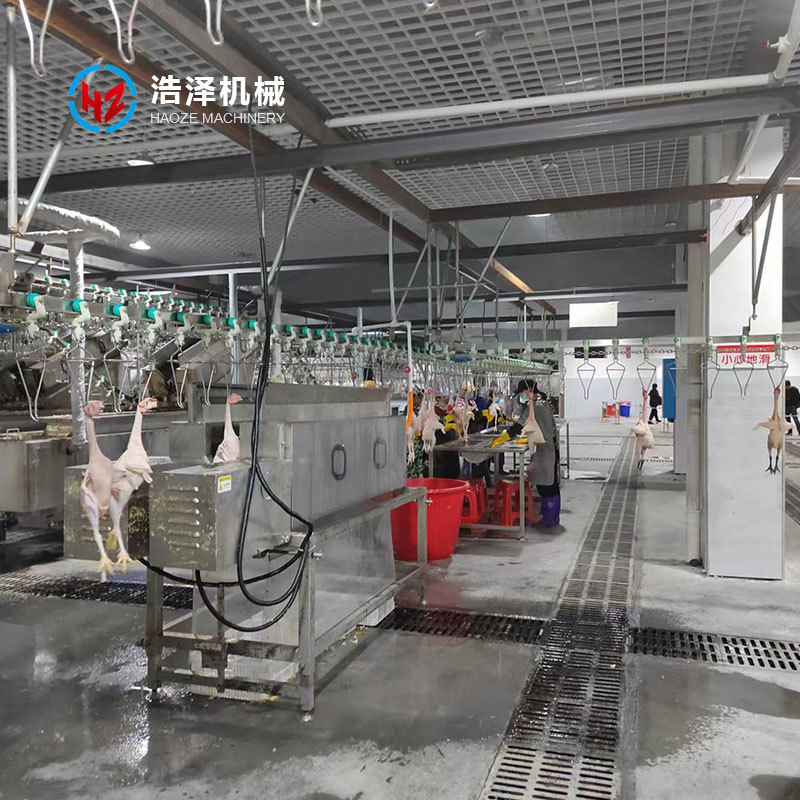

PRODUCT DISPLAY

This equipment is mainly used for cooling chicken feet/chicken heads to achieve the purpose of deacidification and detoxification. The propulsion system and the air blowing system can make the product cool evenly and thoroughly. The pre-cooling time can be designed according to the customer's output or requirements. The power is 4.1kw and the overall dimensions are 4700×800×1050 (mm)

Screw Cooling Machine Pre Chilling Screw Chiller for Chicken Washing

PRODUCT DETAILS

Efficient pre-cooling:

The spiral blade structure is adopted to achieve more complete pre-cooling and rapid deacidification and detoxification.

Uniform cooling:

The spiral propulsion system and the air blowing system work together to ensure the consistency of the cooling effect and avoid local overheating or overcooling.

Comply with hygiene standards:

The equipment is mainly made of stainless steel, which is corrosion-resistant and easy to clean, and meets food hygiene standards.

Stable performance:

Reasonable structural design, stable operation, low failure rate, and improved production efficiency.

Convenient operation:

Users can set the pre-cooling time according to actual production. The operation is simple and convenient, and can flexibly adapt to different production needs.

Energy saving and consumption reduction:

Energy-saving design is adopted to save production costs.

Company profile

Zhucheng Haoze Machinery Co., Ltd. is a technology enterprise integrating design, production and sales of poultry slaughtering equipment and slaughtering lines. It is located in Zhucheng, Shandong Province, China. The company was established in 2015. Since its establishment, it has insisted on serving customers with high-tech and winning the trust of users with superior product quality. The products developed and produced by our company include poultry slaughtering line equipment, including slaughtering equipment lines for chickens, ducks, geese, quails, pigeons, rabbits, turtles, chicks, etc., as well as poultry automatic temperature control double-stirring scalding machines, vertical depilation machines, horizontal depilation machines, poultry precoolers, chicken gizzard de-fat machines, chicken feet processing equipment, gizzard peeling machines, conveyor belts, packaging machines, cutting lines and other products. It can be used in conjunction with foreign automation equipment from the Netherlands, Denmark, Germany and other countries. The product performance has reached the level of similar international products and is in a leading position in China. The company's products have been sold to 46 countries around the world and are ideal equipment for poultry slaughtering manufacturers at home and abroad.

The factory covers an area of 38,000 square meters and has more than 130 employees, including 38 engineers and technicians. The company always adheres to the principle of "details determine quality, quality achieves market", continues to increase investment in scientific research, expand new product areas, and continuously improve the professional level of engineers and technicians. It has formed an efficient and professional service team, which can carry out early process layout design and later installation and commissioning according to user requirements. Haoze Machinery will continue to make unremitting efforts for the development of the poultry slaughtering machinery manufacturing industry.

Haoze Machinery will work hand in hand with you to create a better future!

Product video

Certificate

Our factory

Delivery site

Faq

ENQUIRY

If you have any good suggestions and comments on our company, or want to consult our products, please fill in the form below, and we will contact you at the first time!

RELATED PRODUCTS

Products

Contact us

Zhucheng Haoze Machinery Co., Ltd.

Tel:+86-536-6428777

Phone:+86-15762647779

Whatsapp:8615762647779

E-mail:daniel@haozemachinery.com

Address: Zhucheng Longdu Street Longxiang Street Industrial Park

Follow us